Nowadays, we often hear him that E0 glue plywood or E1 glue type MDF board. Today, PTK Wood will explain that different types of glue. What are these And why are they used in various setting works

First of all, it must be understood that plywood And other wood composites and wood composites, such as particle board and MDF board, are produced using wood materials, either in a thin layer in a plywood case. Or wood pulp in the MDF case is extruded with glue by heat and pressure The most common glues used in the production of these wood are urea formaldehyde (Urea Formaldehyde) or melamine formaldehyde (Melamine Formaldehyde) glue. This evaporation of formaldehyde has effects on the health of both the manufacturer and the product user. Most often found that Exposure to formaldehyde It is in the form of inhaling formaldehyde vapors or touching the skin and eyes. By those who inhale Or touch will show symptoms such as burning eyes, stinging, throat stinging, nose irritation, etc.

Nowadays, we often hear him that E0 glue plywood or E1 glue type MDF board. Today, PTK Wood will explain that different types of glue. What are these And why are they used in various setting works

First of all, it must be understood that plywood And other wood composites and wood composites, such as particle board and MDF board, are produced using wood materials, either in a thin layer in a plywood case. Or wood pulp in the MDF case is extruded with glue by heat and pressure The most common glues used in the production of these wood are urea formaldehyde (Urea Formaldehyde) or melamine formaldehyde (Melamine Formaldehyde) glue. This evaporation of formaldehyde has effects on the health of both the manufacturer and the product user. Most often found that Exposure to formaldehyde It is in the form of inhaling formaldehyde vapors or touching the skin and eyes. By those who inhale Or touch will show symptoms such as burning eyes, stinging, throat stinging, nose irritation, etc.

Nowadays, although formaldehyde is used in the manufacture of a wide variety of products in our daily life such as Used in the fabric and textile industry It is used as a fabric detergent in the production process of finished fabrics so that the fabric will not be wrinkled or wrinkled Or used to make fabric dye, use of tanning, medicine, skin care, nail polish or as a mixture of surface coatings And paints for furniture and various cabinets, but the plywood industry in many countries has taken into account the health of both plywood manufacturers and users. Therefore a standard for controlling the level of formaldehyde in plywood And wood panels to replace other natural wood Containing glue The name of the standard level is different for each country.

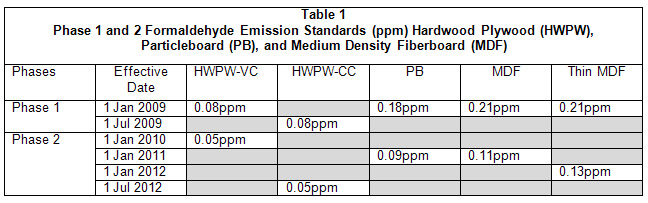

In the United States, California Air Resources Board (CARB) has made a requirement to reduce the amount of formaldehyde evaporated from indoor composite panels such as veneer. And MDF discs The specification is divided into two periods: Phrase 1 and Phrase 2, which began in 2010, and now this standard is often referred to as CARB p2 or CARB phrase 2 itself.

The table below shows the requirements. Formaldehyde level in each type of composite plank The veneer made from HWPW-VC (hardwood plywood veneer core) veneer must have a formaldehyde level not exceeding 0.05 ppm. At present, PTK Wood has produced products. Both types of plywood are HWPW-VC and HWPW-CC for export to USA. And sold to customers interested in this standard product With a certificate to assure customers that our products have passed the CARB p2 requirements.